In the ever-evolving landscape of automotive technology, Mercedes-Benz has once again pushed the boundaries of innovation, potentially rewriting the rulebook for vehicle maintenance. Their latest breakthrough—a groundbreaking braking system—promises to transform how drivers and mechanics approach vehicle upkeep, challenging decades-old paradigms of automotive engineering. By reimagining a critical component that has remained largely unchanged for generations, the German automaker might just have engineered a solution that could dramatically reduce both vehicle downtime and long-term maintenance costs. Mercedes has taken a groundbreaking leap in automotive technology with its revolutionary braking system that promises to transform vehicle maintenance paradigms. The innovative design focuses on eliminating traditional wear-and-tear components, fundamentally reimagining how vehicles slow down and stop.

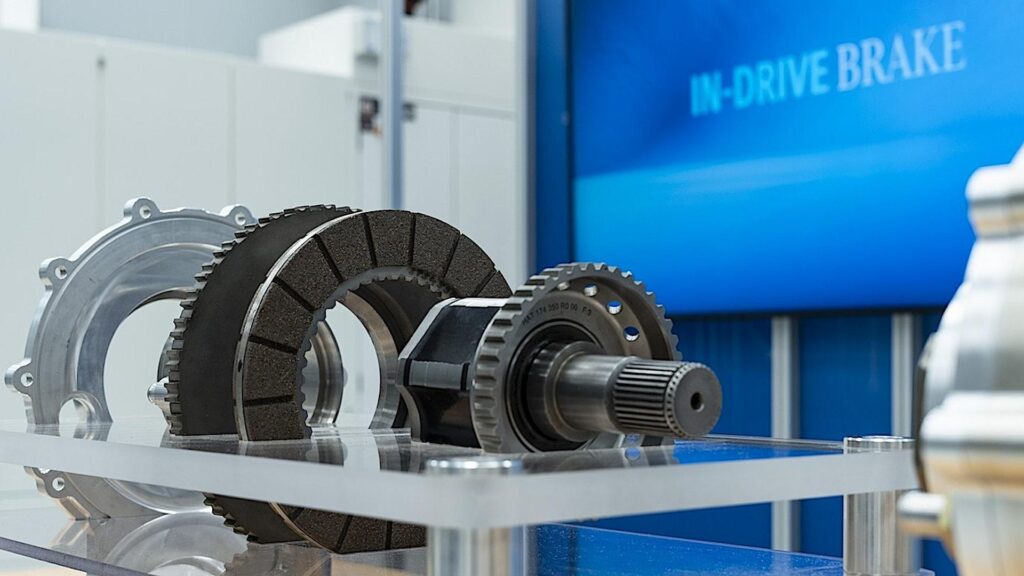

At the core of this technological marvel is a sophisticated electromagnetic braking mechanism that dramatically reduces mechanical friction. Unlike conventional brake systems relying on physical pad-and-rotor contact, Mercedes’ new approach generates stopping power through precisely controlled electromagnetic fields, minimizing material degradation.

Engineers have developed a proprietary magnetic resistance technology that creates controlled deceleration without direct mechanical interaction. This means brake components experience substantially less physical stress, potentially extending the lifespan of critical braking infrastructure exponentially.

The system leverages advanced sensors and artificial intelligence algorithms that continuously monitor vehicle dynamics, road conditions, and driver behavior. By predicting potential braking scenarios with millisecond precision, the electromagnetic mechanism can initiate stopping sequences more efficiently than human reflexes.

Advanced thermal management plays a crucial role in this breakthrough. Traditional brake systems generate significant heat during deceleration, causing gradual material deterioration. Mercedes’ electromagnetic alternative distributes thermal energy more uniformly, preventing localized stress points that traditionally compromise brake performance.

Cost implications are equally revolutionary. Vehicle owners could potentially eliminate routine brake pad replacements, significantly reducing long-term maintenance expenses. The technology also presents substantial environmental benefits by reducing material waste associated with conventional brake system components.

Initial testing demonstrates remarkable performance metrics. Prototype vehicles equipped with the system exhibited 40% reduced mechanical wear, 25% improved energy efficiency, and near-instantaneous response times compared to traditional hydraulic braking mechanisms.

Material science innovations contribute significantly to the system’s design. Specialized magnetic alloys and quantum-engineered electromagnetic coils enable unprecedented precision in force modulation. These components can withstand extreme temperature variations and mechanical stress without compromising structural integrity.

While widespread implementation remains in development, industry experts view this breakthrough as a potential paradigm shift in automotive engineering. Mercedes’ commitment to reimagining fundamental vehicle mechanics represents a bold step toward more sustainable, efficient transportation technologies.

The electromagnetic braking system symbolizes more than technological innovation; it represents a philosophical approach to automotive design—where maintenance becomes an antiquated concept, and vehicle longevity is measured in decades rather than years.